Purification engineering for pharmaceutical and biological industries

Product Introduction

Biological pharmaceutical industry GMP clean workshop interior decoration

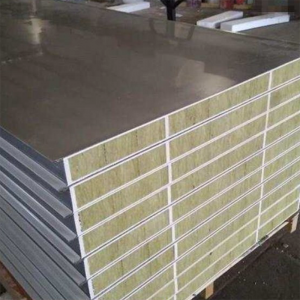

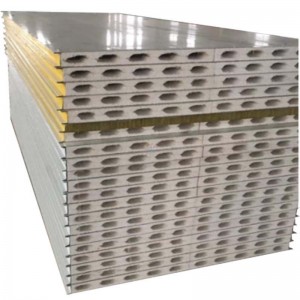

1. Ceiling: with good internal insulation, dust-free and bright, the color is gray or selected by Party A, 50mm thick, and the other parts are made of light gray aluminum plate and metal dark bone ceiling, 0.6mm thick, 600X600, except in the reservoir area, the area before entering the factory and the packaging area.

2. Interval: With double-sided color steel insulation board enclosure and interval, enclosure surface to the top of the ceiling, clean corridor and workshop interval do transparent aluminum alloy half glass window, window sill high 900mm, glass thickness 8mm, high 1200mm, glass door height (2100mm), aluminum alloy window material with special purification material, 45 degrees bevel, and the ground and ceiling Angle do yuan arc and Yin Angle interface, Comply with the standard and sanitary disinfection requirements.

3. Closed door: 800X2100, glass observation window, ball channel lock.

4. Floor: the original cement floor shall be treated with EPOXY resin EPOXY surface layer, 3mm EPOXY quartz mortar between injection molding rooms, wear-resistant and pressure-resistant, and 0.5mm EPOXY resin layer with the color of Apple green or as selected by Party A. Dust-free clean and bright, easy to clean, do not accumulate dust bacteria. Or floor materials and treatment methods shall be selected by Party A.